Next gen threads printed

Research engineers have used laser printing technology to produce waterproof e-textiles in minutes.

Research engineers have used laser printing technology to produce waterproof e-textiles in minutes.

Scientists from RMIT University have developed a cost-efficient and scaleable method for rapidly fabricating textiles that are embedded with energy storage devices.

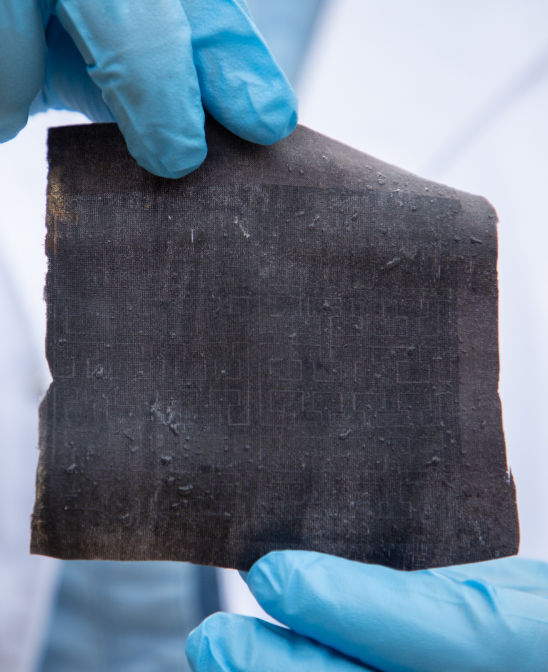

In just three minutes, the method can produce a 10 by 10cm smart textile patch that is waterproof, stretchable and readily integrated with energy harvesting technologies.

The technology enables graphene supercapacitors – powerful and long-lasting energy storage devices that are easily combined with solar or other sources of power – to be laser printed directly onto textiles.

In a proof-of-concept, the researchers connected the supercapacitor with a solar cell, delivering an efficient, washable and self-powering smart fabric that overcomes the key drawbacks of existing e-textile energy storage technologies.

The growing smart fabrics industry has diverse applications in wearable devices for the consumer, health care and defence sectors - from monitoring vital signs of patients, to tracking the location and health status of soldiers in the field, and monitoring pilots or drivers for fatigue.

Dr Litty Thekkakara, a researcher in RMIT’s School of Science, said smart textiles with built-in sensing, wireless communication or health monitoring technology called for robust and reliable energy solutions.

“Current approaches to smart textile energy storage, like stitching batteries into garments or using e-fibres, can be cumbersome and heavy, and can also have capacity issues,” Dr Thekkakara said.

“These electronic components can also suffer short-circuits and mechanical failure when they come into contact with sweat or with moisture from the environment.

“Our graphene-based supercapacitor is not only fully washable, it can store the energy needed to power an intelligent garment – and it can be made in minutes at large scale.

“By solving the energy storage-related challenges of e-textiles, we hope to power the next generation of wearable technology and intelligent clothing.”

The research analysed the performance of the proof-of-concept smart textile across a range of mechanical, temperature and washability tests and found it remained stable and efficient.

Print

Print